Is your sewing machine unthreading? Find out why your thread keeps coming out of the needle and what to do here.

Hey y’all, today we’re going to tackle problems with a sewing machine unthreading. When I taught sewing in public school, I always had students who had trouble with this. It can be sooooo frustrating to start sewing your fabric just to realize your needle has no thread and there are no stitches. This post will cover reasons why your needle keeps unthreading and what to do about them so you don’t have to constantly rethread.

Reason #1: The Takeup Lever Isn’t at the Top

The video below summarizes what to do if your needle is unthreading as you begin sewing. This is one of the most common reasons for unthreading. You can also watch on YouTube here if you prefer. And further in this post I have more troubleshooting tips to check for sewing machine unthreading problems.

The number one reason my students had issues with their needle unthreading was that they would stop stitching without their needle in the highest position possible. Then they would cut their thread. On the next seam there wasn’t enough thread to reach the sewing machine needle as the take up lever went up. And boom, unthreaded needle!

You can tell if your needle is all the way up by looking at the take up lever. On vintage machines the take up lever might stick out. You can see it on n my vintage Singer sewing machine pictured below. But on newer machines it might be hidden behind the machine casing. On newer machines there is a window so that you can make sure the lever is all the way up. I told my students to always crank the handwheel toward them until they could see the take up lever at the top before releasing their presser foot and cutting the thread.

My sewing machine now has a feature with the automatic thread cutter that makes sure the take up lever is all the way up automatically before it cuts the thread. I love that because this problem isn’t one I run into very often anymore.

Reason #2: The Machine is Not Threaded Correctly

If you are sure the take up lever is at the top, but you still have a sewing machine needle unthreading, the next thing to check is to make sure your machine is threaded the correct way. If this is a new to you machine, make sure you’ve read the user manual. Some machines have particular quirks for threading. Most machines do follow a similar thread path though. Even with an old familiar machine, it’s possible to accidentally skip a step. So try releasing the presser foot, unthreading the machine, and rethreading. Make sure to do this both with the top thread and the bobbin thread.

One other common mistake I see is trying to thread with the presser foot down. On the majority of machines this means the tension discs are engaged. If you thread with the tension engaged, the thread won’t sit properly in the discs and you’ll have issues when you start stitching.

Reason #3: There Is A Problem With The Thread or Needle

If your thread is too thick for the eye of your needle, it will shred and you’ll have thread breaks. This can also happen when using old or low quality thread. You can see more about thread types and weights here. And you can see more about machine needles here. The bottom line is to make sure that your needle and thread are matched. Don’t use the wrong needle for your thread.

One other thread problem to check is if the spool of thread unwinds smoothly. Sometimes it can get wrapped around the spool pin, or caught on a nick in the spool cap. Correct those issues and you won’t have your sewing machine unthreading.

Needle problems can include a bent needle,

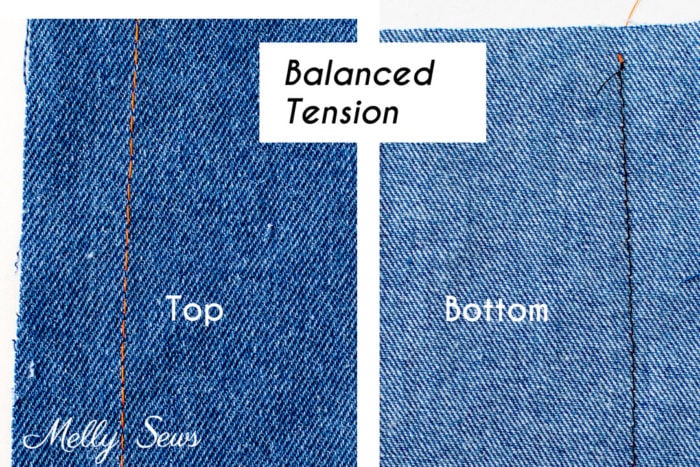

Reason #4: There is a Tension Problem

The interplay of the upper thread tension and bobbin tension creates must be balanced. If you don’t have correct tension, your thread can break and unthread your needle. You can see more about tension in this post. I include a visual example of how the top and bottom threads work together. Understanding that interplay helps you identify which way to adjust the tension dial.

Conclusion

There are many reasons why your sewing machine might be unthreading. These include:

- Take up lever not all the way up

- An incorrectly threaded machine

- Problems with thread or needle or the combination of the two

- Problems with the sewing machine tension

Hopefully this post has given you a good idea of what to look for so you can return to happy sewing!

Becky Bolyard

Thanks for this post. This happens to me quite often.

Peg

Great Info. I am always telling students to make sure there is a tail. Just pull at end of stitching after cutting. But now I have some more tips to share. Thank you.

I love reading you.

Beverly Largent

Excellent teaching as you always deliver what is needful! No matter how long I’ve been sewing, learning or refresher learning eah and every time…. thank you for your teaching and reminding…

Shiela G

I’ve always wondered why this happened! Fabulous help! Thank you!

Bhrooklyn

You have answered my questions and solved my problem!!! I am ELATED!!!!because I wasn’t able to finish my garment, and now I am moving right along smoothly!!! THANK YOU SO MUCH!!!