Learn how to choose sewing machine needles to sew denim, as well as thread and sewing techniques for success.

Hey y’all, it’s jeans sewalong week! All week I will be sharing tips and tutorials to get you sewing your own jeans. First up for me are tips to sew denim, including choosing the right denim needle and thread.

Denim is one of those fabrics people avoid because it’s thick, which means that when you have layers of fabric it just gets thicker. But if you handle it correctly, sewing your own jeans is not that hard. Really. I promise – I sewed mine in an afternoon. And if you just want tips on sewing thick fabrics in general but not denim specifically, check out this post.

For the TLDR version, check the list below. And for more reasoning behind these denim sewing tips, keep reading.

Top Tips to Sew Denim

- Cut with sharp scissors

- Use the right needle

- Use the right thread

- Use a bumper or a leveling foot (J foot)

- Go slow

- Use a mallet

Really that’s all there is to it. But let’s delve into each a little more in depth.

This post contains affiliate links. As an Amazon Associate I earn from qualifying purchases. All affiliate links are identified with (affiliate link) after the link or a commissions earned statement above the link(s).

Sharp scissors

Really, this one is kind of obvious. This is my favorite pair of dressmaking shears (affiliate link). I’m not sure when, in sewing, you’d want dull scissors. Sharp scissors are particularly important for thick fabrics, which, by virtue of their thickness can be harder to cut. Also stretch denim has polyester in it, which can dull scissors. And to keep my good scissors sharp, I visit a knife sharpener every so often for a tune up. I’ve had these scissors for decades and they’re still going strong. Note that newer versions might have enameled handles, but the blades are the same.

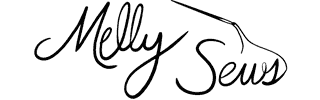

Use the correct needle

I have another in depth post about different types of needles, and in that post I mention that I use the same type and size of needle for 80% of my projects. Denim projects are in the 20% of projects where I will change to a different needle size and a new needle.

There are jeans needles that you can buy especially for sewing jeans. If you don’t want to buy specialty needles, just make sure to have at least a size 90/14 universal needle (100/16 for thicker denim). Needles should be matched to the thickness of the fabric you’re sewing. Denim is at least a size 90/14 or 100/16, while something like silk charmeuse would be a 70/11 and a medium weight linen would be an 80/12.

Remember that Europeans and Americans size their needles differently, which is why you’ll see two numbers on sewing needles. The larger number, the bigger the needle for both systems. European needle sizes refer to millimeter measurements, in that a 100 needle is 1 mm in diameter. So if you see a 100/16 needle, the 100 is the European size and the 16 is the American size.

Also note that a universal needle splits the difference between a ball point needle (for knits) and a sharp point needle (for wovens). Because most modern denim for garments has some spandex for stretch in it, a universal needle should be ideal. But if you’re having trouble with non stretch denim it might be worth switching to a sharp needle, and if you’re working with very stretch denim you might have better luck with a stretch needle. Always do some sample sewing on fabric scraps from your project to find the best needle type for your purpose.

One more note on needles for denim – you may want to have use twin needles for the parallel rows of topstitching that jeans often feature. I mostly use a twin needle for knit fabrics, but for use with denim you’d want a universal twin needle, not a ballpoint needle.

Use the right thread

For the regular seams, I use all purpose thread, just like I do for the vast majority of my sewing. This article goes more in depth about thread types and weights.

For the topstitching that comes with flat felling (a common seam technique for jeans; check this post for a tutorial), I switch to Heavy Duty all purpose polyester thread. Note that this thicker thread is also something that requires a bigger needle.

Tip: some sewing machines (my vintage one) hate the cotton thread that is marketed as jeans topstitching thread. My machine shreds this stuff and I spend all my time using it trying to get pretty topstitching but instead dealing with thread breakage.

If your machine is doing this, first try switching to a bigger needle, which will have a bigger eye. But if you do that and still see the thread balling up on the scarf (the part of the needle above the eye) and then breaking, switch to a thread made from polyester. Upholstery thread can also be a great substitute – it looks thicker like the topstitching thread you’re used to seeing on jeans, but it’s smoother than the cotton jeans thread, and so it is less prone to making your machine anger and shred it.

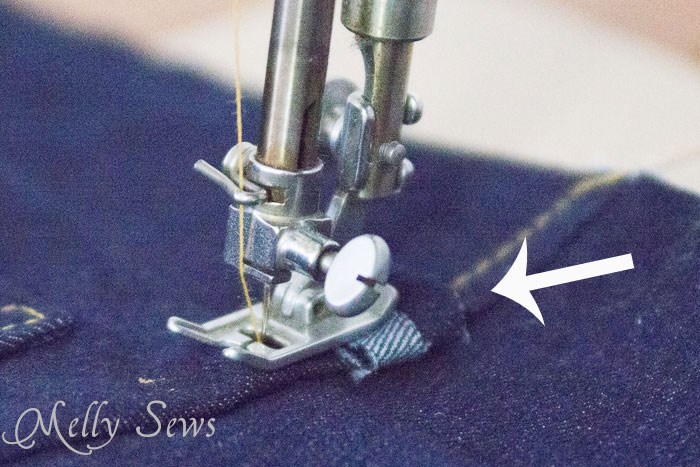

Use a bumper or a leveling foot

I don’t actually even know that this is what it’s properly called, this is just what I call it. Basically a bumper is a scrap of denim you keep near your machine while sewing. When you’re sewing over thick areas, like the place where the two seams cross at the back yoke, your machine might want to stall because of the presser foot being unbalanced. Bumper to the rescue! Fold it up, place it behind or in front of the presser foot to level the foot out and allow you to continue sewing.

If you have a newer machine, it might have come with a J foot, also known as a leveling foot (affiliate link). The video below shows how to use that, and if you can’t watch it below you can also watch it on YouTube here.

Go slow

This, like sharp scissors, is kind of an obvious one. There are lots of places on the jeans where you might even want to handcrank the flywheel to get through. And that’s perfectly fine – it’s easier to slow down and do it right than to have to pull out the seam ripper and take out stitches.

Use a mallet

This is an unconventional sewing tool, but a mallet is handy to hammer down thick seams before putting them through the sewing machine. This will flatten the seam a bit, but it also breaks down the fibres a little and makes them easier to pierce with a needle.

Anne

Great tips!! I’m glad to know I can just use a heavier needle instead of having to buy a special denim needle. I am so bad about not using the right needle. I’ve got a Craft Gossip post scheduled for later today that links to your and Sabra’s posts:

http://sewing.craftgossip.com/tips-for-sewing-on-denim-and-cutting-jeans-pattern-pieces/2014/03/17/

–Anne

Amy

Wow! A bumper! This is the first I’ve heard of this tip. I can’t wait to try it out. My machine always gets mad at me on thick seams…

Robin

Annies Attic catalogue has a gadget that works better then a bumper, check

it out. Its called a Jean a Ma Jig. They are 3.48 each!

Debbie Reaves

I have one of these, and it works great!

Drea

Mine too. This is a great tip. Bumper

Stephanie

Linking up here! http://swoodsonsays.com/sew-a-long-calendar/

Deanna {sewmccool}

It’s actually called a “Hump Jumper.” (and no, you can’t only use it on Wednesday, hump day). It’s actually a trademarked tool, so probably generically calling it a bumper when not actually using the tool is correct! But if you want the actual tool….just Google “Hump Jumper” and you’ll see it. 🙂

Rachel

I’ve never heard the bumper trick, handy! My machine hates denim thread too, I’ll have to check out the alternatives

Christy Dixon

Thanks for the advice on upholstery thread! I’ll try that!

Txiqui

For me however, I work much better special denim needles even noticed my machine costing less work through the thick areas, even using small numbers. The machine is much smoother, and if we use above coarse thread, needles jeans have a special recess prevents skipped stitches .. I always use the needles jeans 130/705 H-J , even for sewing thick fabrics, when I want to use thick threads .

Linda Antilley

You’re correct on the Denim Sharp needle. When you are sewing any fabric that is closely woven or even painted, you need the needle to pierce the fabric and make a “hole” that keeps the thread from being held tightly to the back of the needle. If that happens, your bobbin cannot catch the thread to make a stitch. Any time you have skipped stitches, check the size and type needle you are using. Universal needless tend to slide between the woven fibers of your fabric and may cause skipped stitches. There is so much more to share on this. Please contact me at msflair50 @gmail. com. I’ll be happy to answer your questions/concerns. Knowledge is power!

Heather

My grandmother’s go-to with sewing denim was a bar of soap. In spots that are heavier, a little soap on the spot helps lubricate the needle, so it’s less stress on the needle and the machine. It kept her under-powered machine happy, in spite of the abuse we gave it with denim.

Robyn

I have never heard of a bumper either, I just lift the foot and turn the machine by hand until over the tough spot.

Linda Antilley

It is called a “Hump Jumper” or “Jean-a-ma-jig”, usually has two “heights” or thicknesses – one on each end – and is placed behind the pressure foot to level it out so the feed dogs will do their job, continuing to move the fabric along despite the thickness of the offending seam. It could be moved to the front to continue once it has sewn over the thick seam to keep the presser foot from “falling off” the thick seam in the front. Since it has “toes” with an opening for the needle to pass through, sewing with it is a cinch! They are available at most sewing machine dealerships and through Nancy’s Notions. Well worth having in your sewing supplies. Sew smarter, not harder!

Cathy G

I hem jeans for my clients, who are friends, family, and neighbors. The tool I use is called a Jean-a-ma-jig…it raises up the “downhill” side of my presser foot when I’m sewing over extra thick areas. I also bought a machine that has a stronger motor that can punch through things like canvas and denim, vinyl, and faux leather. I used to break many needles when hemming or mending jeans…now, not so much needle-breakage.

Marigold

Oh, man! Where were you this weekend when I was messing up a denim skirt? 😉

Mysti

Thanks! Glad I read this before I turn my daughters jeans into Capris.

Jim

my Bernina 1080 came with a device called a height compensator. It’s 3 small strips of plastic riveted together so you can you can combine them for three different thickness. You place the compensator under the trailing edge of the presser foot at the denim seam and it glides smoothly over the seam. The plastic allows the presser foot to “slide” while it presses the denim down for a good bite against the feed dog. This is Bernina’s “bumper”.

Cletisann Mckellar

Love the bumper idea.

Elenir Cezimbra

I started with Denim projects short ago and your tips are helping through this learning process. Thank you very much!

Bev Monroe

You can hammer both the inseam and out seam of your jeans before hemming them. Both seams will not have such a “hump” and will be easier to go over!

JNormann

Hammering is a good trick to use on those thick joins, but, don’t forget to use a scrap over them to protect from any residue on your hammer.

Also, it’s the thing now to use the salvage as a, decorative party of the denim project. Just remember that the salvage will shrink up tighter than the cut denim edge. Using it as a long seam may end up scrunchy after a few washes. Pocket edges that get stretched make a good place for salvage use.

Esmeralda ONeill

On the denim sewing what size thread should be in the bobbin because when I use the heavy weight my machine acts up. I have a Bernina 830.

clehman

I love my Jean-a-ma-jig It works wonderful;

june

Thanks so much for the bumper and needle and thread tips. Just yesterday neeed this.

MrOwl

Thanks for the great tips! If you have access to a 3D printer, this jean a ma jig clone is as simple as it gets:

https://www.thingiverse.com/thing:1816985

If you prefer the hump jumper, this maker created two sizes: https://www.thingiverse.com/thing:2345201

Happy sewing!